In this piece of the Building Blocks series, we take a look at tar sands, possibly the world’s largest available source of oil. We discuss in this order: what and where are tar sands, how tar sands are turned into fuel, what are the economic and environmental implications of the tar sands, and then have some conclusions.

What and where are tar sands?

Tar sands are mixtures in some proportion of bitumen (tar), water, and sand or clay. The phrase tar sands is in many ways misleading, as the bitumen contained in the sands is not actually chemically similar to tar, which is a processed, distilled byproduct of petroleum. Bitumen is more similar to asphalt than to tar. Because bitumen is not very similar to petroleum and must be processed before it can be refined, oil produced from tar mining and refining is usually referred to as synthetic oil (crude) or non-conventional oil.

The chemical composition of bitumen is substantially different from that of petroleum. This is why it is so hard to extract. In fact, only with the recent advent of new technologies for mining and extraction have bitumen reserves come to be counted as part of the proven oil reserves of countries. The bitumen from tar sands is so viscous that it is difficult both to separate it from the sands and to transport it, as it must be liquid enough to flow in a pipeline in order to be transported cheaply. Furthermore, the refining of tar sands is more difficult than that of crude petroleum.

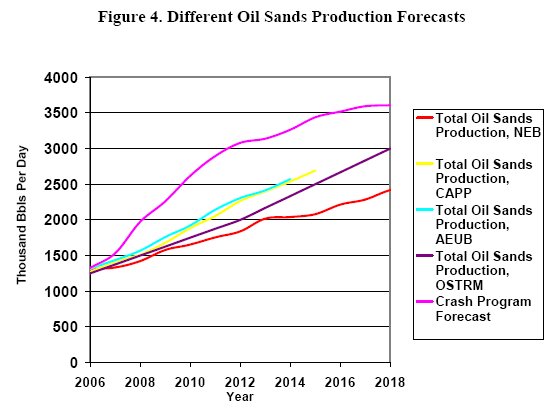

The majority of the world’s tar sands are located in Alberta, Canada, which nominally contain around 1.7 trillion barrels of oil in tar sands equivalents. Current estimates of the recoverability of this oil stand around 10%, giving total recoverable reserves of around 170 billion barrels. Some people claim that modern technology will allow recovery rates of 20%. For comparison, Saudi Arabia, the only country with greater reserves, has proven reserves of about 240 billion barrels, if you believe its statistics. Here’s a graph of current projected oil production from the Alberta tar sands in Canada.

The scale on the left is in thousands of barrels per day of production (a barrel is equivalent to 31 gallons or 117.3 liters), and the scale on the bottom is in years. The different lines represent different agencies’ estimates of future production. We can see they all agree on one thing: synthetic crude production from the tar sands is only going up.

The scale on the left is in thousands of barrels per day of production (a barrel is equivalent to 31 gallons or 117.3 liters), and the scale on the bottom is in years. The different lines represent different agencies’ estimates of future production. We can see they all agree on one thing: synthetic crude production from the tar sands is only going up.Venezuela’s Orinoco tar sands may have even more oil than Canada’s, but exploration is ongoing. These are only now beginning to be exploited. Other, far smaller tar sands deposits are scattered around the world, with some in Utah, some in the Middle East, and some elsewhere.

How are tar sands turned into fuel?

The process of turning tar sands into fuel is threefold. First, the sands have to be strip-mined from the ground. Second, the sands must be processed so that they flow as liquids and not as solids, as the bitumen is highly viscous. Third, the now-liquid bitumen must be processed and refined into standard byproducts like gasoline.

Extraction and Mining: In the rare cases when the bitumen (or extra-heavy oil, which has very similar problems) is liquid enough, the heavy oil is simply pumped directly. However, the vast majority of the reserves of bitumen are not accessible to this method. For these more viscous fluids, there are two major methods of extraction. Each of these has technical sub-disciplines and specific terminology, but we will give an overview of how they work without bogging down in specific design implementations.

Strip mining is the original way to extract tar sands. It is only efficient when the tar sands are concentrated close to the surface of the ground, with a minimal amount (by minimal we mean on the order of fifty meters) of extraneous material on top of them. This is the case in many locations in Alberta. The current state of the art uses massive mobile mechanical shovels and equally massive dump trucks (some with a capacity of 400 tons or more). These sands are then transported to a liquefaction plant.

That said, over 80% of the world’s tar sands are not accessible by strip mining. For these, the major method of extraction involves fluid injection and gravity assisted flow to a well. First, two wells are drilled into the sands, with one well going substantially deeper. Then, a pumping mechanism is installed in the deeper well. Either steam or a petroleum solvent is then injected in massive quantities into the higher well. With steam injection, what then happens is that the steam raises the temperature of the bitumen so that it flows freely, like a less viscous liquid, and then it drains into the lower well, from which it is pumped out. With a petroleum solvent (this method has been widely researched but not yet implemented on a large scale), a chemical reaction happens that dissolves the bitumen into the solvent. The solution of solvent and bitumen then flows into the lower well, from which it can be pumped out. This method has the advantage of much greater energy efficiency than steam injection, for the obvious reason that producing the vast quantities of steam necessary for steam injection requires an equally vast amount of energy.

Liquefaction: The resulting bitumen is then liquefied and processed. By adding hot water to the bitumen and then agitating it, the plant separates the bitumen from the sand and other contaminants. The slurry of bitumen, sand, and water, upon being agitated, separates, the bitumen floats to the top, where it is skimmed off. Excess water is then removed, resulting in bitumen ready for refining. The remaining water and sand contains countless toxic chemicals, and it is invariably pumped into a “tailings pond.” These ponds themselves are highly toxic, and there have been many reports of dead wildlife (particularly birds), who have either directly or indirectly consumed the water.

Refining: Because bitumen is so heavy (dense), compared to all types of conventional crude, it requires specialized refineries to process it. These refineries either “upgrade” the bitumen into synthetic crude (syncrude) and then conventionally refine it (which is more common) or directly process it into petroleum byproducts (which is less).

Both processes are similar, so we’ll treat them as one. Essentially, crude oil refining involves bringing the crude oil to a certain temperature and then raising the temperature in stages so that different parts of the oil boil off at different times. These are separated and further processed to improve their performance. Lighter fuels, like jet fuel and gasoline, boil off first; heavier materials, like fuel oil and asphalt, are left behind in the bottom of the container. These are then separated in a different way.

The peculiar concern of bitumen refining is that bitumen is very similar to asphalt; it does not naturally contain very much of the more volatile, lighter hydrocarbons like gasoline. The chemical difference is that the bitumen molecules are simply larger than those of gasoline, diesel, or jet fuel. So, in a bitumen refinery, the bitumen is first raised to a very high temperature, at which these large molecules “crack” into smaller ones. These smaller molecules, still mixed together, then closely resemble conventional crude oil. This mixture, which is referred to as the synthetic crude, can then be refined conventionally.

What are the challenges, both environmental and economic, for the widespread use of tar sands?

The economic challenges are fairly straightforward. Because of the involved nature of the process to excavate and refine bitumen from tar sands, capital and ongoing costs are substantially higher on a normalized per barrel basis than conventional oil. However, it estimated that the price threshold for crude oil for profitability, at least in Canada, rests around $40-$50 per barrel. With oil prices far north of this threshold (and new technology reducing the costs of production), this is not a substantial barrier to production. The high capital costs may proved to be an issue if credit conditions remain tight, but many oil companies can usually provide internal funding for exploitation of reserves or find a major company as a partner.

The environmental challenges are massive. Although tar sands exploration does not release methane into the atmosphere (one of the main sources of CO2e emissions for traditional oil production), it does have numerous other problems that outweigh this sole benefit.

Carbon: Production of synthetic oil from bitumen is much more energy-intensive (and therefore carbon-intensive, as few renewables exist in the Alberta tar sands) than conventional crude oil production. As a result, despite the lack of methane by-emissions, synthetic crude from tar sands operations carries a carbon debt of between 1.5 and 3 times as much as regular crude. Many different groups, either from industry or the environmental movement, have estimated this number, and, accordingly, these estimates vary greatly.

Water: The slurry water mentioned above, in which the bitumen is agitated from the oil-sand-water mixture, is highly toxic and ends up in massive “tailings ponds,” which are essentially man-made repositories for this toxic water. There have been widespread reports of the deaths of birds who drink from these ponds (some of which are pictured below with lesions and tumors); the boreal forest, in which the Canadian tar sands are located, are among the largest remaining bird habitats on earth.

Furthermore, there is a significant risk that water from the tailings ponds will leak into the nearby rivers, in Alberta the Athabasca, thereby contaminating one of Canada’s most pristine rivers. Oil sands extraction already consumes more freshwater than every single home in Alberta, or twice the freshwater consumed by the entire city of Calgary.

Furthermore, there is a significant risk that water from the tailings ponds will leak into the nearby rivers, in Alberta the Athabasca, thereby contaminating one of Canada’s most pristine rivers. Oil sands extraction already consumes more freshwater than every single home in Alberta, or twice the freshwater consumed by the entire city of Calgary.Air: Although ambient air quality has not decreased in the vicinity of the tar sands in most major pollutants (the major exception being hydrogen sulfide, H2S), it is likely that the increased power generation required to power the operations will decrease air quality in key areas, like PM2.5, Ozone, and Carbon Monoxide.

Conclusions:

Tar sands represent a major environmental threat. By increasing the supply of oil, they serve to depress prices and prolong the dangerous age of oil in which we find ourselves. Because the extraction of their oil is so carbon-intensive, they pose a major climactic threat, as with each passing day they represent a greater proportion of the recoverable oil in the world. This oil is far worse for the climate than regular crude. Furthermore, tar sands exploitation poses a direct local environmental threat, poisoning the water of and destroying the natural ecology of a central portion of the previously pristine boreal forest.

That said, the Canadian tar sands (neglecting the unexploited Venezuelan sands) do provide a politically stable source of oil to the United States, and will play an important role in the petro-politics of the next twenty years. We are already seeing this in the debate over U.S. Imposed penalties placed on syncrude from Canadian tar sands for their carbon impact. Also, many Midwestern states are considering increasing their refinery capacity in order to access this Canadian oil. More will come from this increasingly important source of the world’s oil.

Further Readings:

Wikipedia

NRDC on "dirty fuels"

Elizabeth Kolbert in the New Yorker on her visit to tar sands

Jiri Rezac’s pictures from the tar sands.

No comments:

Post a Comment